Benefits Of Concrete Polishing In Hawaii

If you're looking to upgrade your floors from drab to fab, listen up! Concrete polishing is the answer to all your flooring woes. It's like taking a plain Jane concrete floor and giving it a makeover fit for Hawaiian royalty. It transforms boring, gray concrete into a stunning, high-gloss work of art.

Plus, it's not just a pretty face; concrete polishing has a slew of advantages that will have you saying "mahalo" to this flooring option. So, let's dive into the benefits of concrete polishing in Hawaii and find out why it's the perfect fit for your next flooring project.

Benefits of Concrete Polishing

- Stain-Resistant Surface

- Affordable Flooring For Long-Term

- Enhanced Reflection Rate and Illuminance

- Requires Less Maintenance

- Slip-Proof Surface

- Eco-Savvy and LEED Certified!

- No Plant Shutdown or Tire Wear

- Efflorescence-Free Flooring

Stain-Resistant Surface

Concrete polishing works its magic by transforming porous concrete into a dense and tight surface through the processes of densification and sealing. The result? A floor that is impenetrable to water, oil, and other unwanted contaminants, keeping your floor looking fresh and clean!

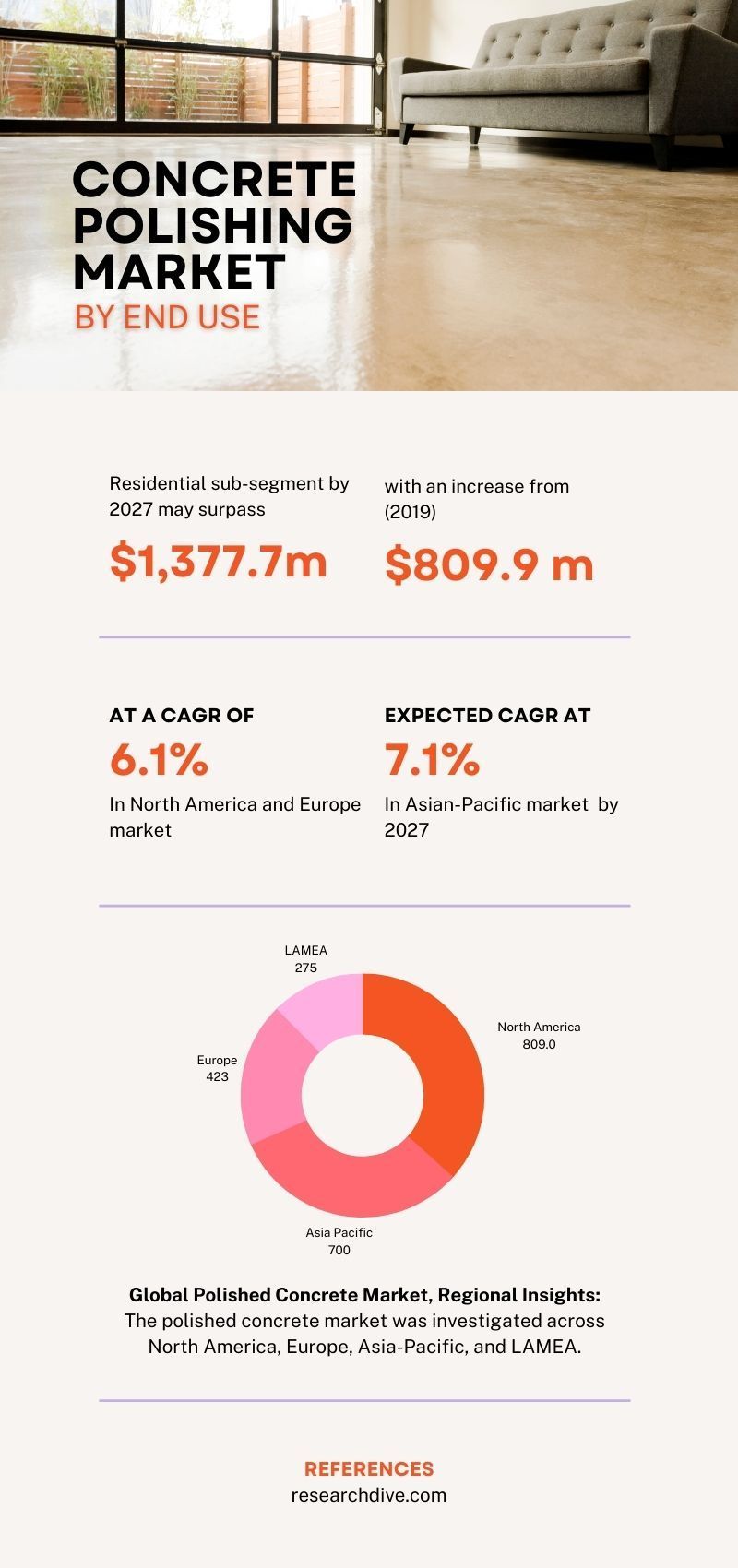

Affordable Flooring For Long-Term

Polished concrete offers a fantastic return on investment with its savvy energy-saving and maintenance-minimizing features. Its reflective surface enhances ambient lighting, eliminates the need for frequent upkeep like waxing, and even reduces tire wear in specialized applications.

Enhanced Reflection Rate and Illuminance

Polished concrete flooring has the unique ability to reflect light and amplify the brightness in your facilities. This not only improves the aesthetic but also helps to lower energy bills and boost safety levels. The improved ambient lighting will give your facility a radiant glow, putting it in the best possible light.

Requires Less Maintenance

Regular flooring options like tile and linoleum need constant elbow grease to keep them looking clean and presentable.

But with polished concrete, you won't have to worry about that! The surface is compacted, making it more resistant to stains, so there's no need for excessive cleaning. And the best part? It keeps its shine without any waxing or stripping treatments.

Slip-Proof Surface

Don't let its glossy appearance fool you; polished concrete floors actually increase slip resistance. The mechanical grinding and flattening processes enhance the coefficient of friction, making it safer than regular concrete. In fact, polished concrete often surpasses the OSHA standards for floors (ASTM C 1028).

Eco-Savvy and LEED Certified!

Not only does it give new life to existing concrete surfaces, reducing the need for additional materials, but it's also a breath of fresh air in terms of air quality. It contains no harmful volatile organic compounds (VOCs), making it the perfect choice for any LEED project certified by the U.S. Green Building Council.

No Plant Shutdown or Tire Wear

No more surface stress, delamination, and other problems that arise as concrete ages. Mechanical polishing removes the top layer, revealing a stronger and smoother surface, ready to withstand high impact and abrasion.

Additionally, there’ll be less to no rough and uneven textures that cause your tires to wear down. The polishing process levels the joints and creates a uniform surface, reducing the risk of abrasion.

Efflorescence-Free Flooring

Unpolished concrete is prone to efflorescence, where dust particles rise to the surface. This leads to the dusting and peeling off of epoxies, which can incur hefty maintenance costs.

But, with polished concrete, you can bid adieu to efflorescence and the expenses that come with it. A sleek and shiny floor without any dust—now that's a deal worth considering!

Perfect Solution for Your Floor: Concrete Polishing In Hawaii

Confused about whether polished concrete or epoxy coatings are the ideal flooring solution? Let us take the stress out of the decision-making process. Schedule a comprehensive consultation and receive a complimentary quote. Find the perfect flooring choice that caters to your specific requirements today!