Innovative Materials and Techniques: Oahu Concrete Professionals' Cutting-Edge Methods

One of the greatest mistakes that a company could make is to not innovate and be stagnant. As we all noticed, staying ahead of the curve with new innovative techniques and materials is a pillar in the construction industry for delivering high-quality and durable structures. One of the best construction companies that always keeps up is the Oahu Concrete Professionals. They invest their time and effort in new innovative discoveries and they maintain their position at the forefront of this advancement by utilizing state-of-the-art methods and materials to ensure their works can go beyond the industry standards. In this article, Oahu Concrete Professionals are willing to share their cutting-edge techniques and innovative materials to deliver outstanding results.

High-Performance Concrete Mixes

Every contractor should be fully knowledgeable about the different types of concrete mixes and their PSI strength. However, with the continuous innovation of Oahu Concrete Professionals, one of their primary milestones is the utilization of high-performance concrete or HPC for the shorter term. The development of this concrete mix is one of the primary innovations in the concrete industry. This type of concrete is designed to provide enhanced properties, such as increased strength, durability, and workability. Oahu Concrete Professionals is one of the concrete contractors who employ HPC to ensure that their structures can withstand the high humidity, salt air, and frequent rainfall in Oahu, Hawaii.

Key Components of High-Performance Concrete

Supplementary Cementitious Materials

Innovative materials like fly ash, slag cement, and silica fume are good solutions to substitute a portion of the cement in the mix. By adding these types of SCMs, they can enhance the durability and sustainability of the concrete by reducing permeability and increasing its resistance to damaging chemicals.

Superplasticizers

This add-on mixture can significantly improve the workability of concrete to allow it to be placed more easily without compromising its strength.

Fibers

The addition of steel, glass, or synthetic fibers can make the concrete stronger and more durable by improving the tensile strength and crack resistance of the concrete.

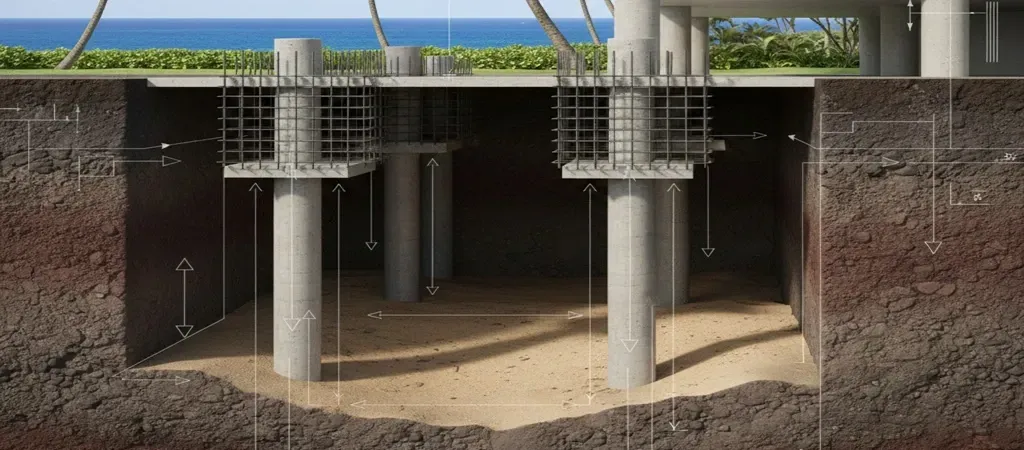

Advanced Reinforcement Techniques

Reinforcement is really important in handling tensile stresses and enhancing the overall performance of the concrete structure. Another innovation that Oahu Concrete Professionals employ is the advanced reinforcement techniques that maximize the structural integrity and longevity of their projects.

Fiber-reinforced polymer (FRP) Bars

If you are looking for a better alternative solution to steel reinforcements, FRP bars are the best choice because of their high resistance to corrosion and a higher strength-to-weight ratio. Because of the saltwater exposure due to Oahu's coastal environment, steel reinforcement can corrode rapidly. That is why these bars are really helpful in the construction industry in Oahu.

Post-Tensioning

Post-tensioning is a process or method where the tendons within the concrete are tensioned after the concrete is cured. It is a necessary technique nowadays for constructing high-rise buildings, bridges, and other large-scale structures. This innovative technique allows for longer spans, reduced material usage, and greater control over cracking and deflection.

Innovative Formwork Systems

The concrete placement's efficiency and quality depend on the formwork systems used. This is the reason why Oahu Concrete Professionals use innovative formwork technologies to reach the precision and efficiency of concrete placement.

Modular Formwork

Modular formwork systems are composed of prefabricated panels that you can assemble and disassemble easily. Oahu Concrete Professionals utilizes these systems because they provide many advantages, such as reduced labor cost, faster construction time, and improved safety. Moreover, modular formwork ensures the quality and accuracy of concrete placement consistently.

Self-Consolidating Concrete (SCC)

This advanced solution is a very flowable concrete mix that can easily spread into place and fill formwork without the help of mechanical vibration. SSC makes it ideal for complex formwork and densely reinforced sections. The use of this property can significantly reduce labor costs, minimize noise pollution, and ensure a high-quality finish.

Sustainable Concrete Solutions

Sustainability has been a growing concern, particularly in the concrete industry of Oahu, Hawaii. That is why Oahu Concrete Professionals started adopting eco-friendly solutions to minimize their environmental impact while maintaining the excellent status of their work.

Green Concrete

Not literally green, but green concrete is created using recycled materials and other by-products, such as fly ash and slag cement. This improvement not only decreases carbon emissions but also enhances the durability of the concrete and reduces the reliance on regular cement.

CarbonCure Technology

This agent injects recycled CO2 into fresh concrete during the mixing process. This process improves the comprehensive strength of the concrete while reducing the overall carbon footprint by trapping CO2 permanently. Because of its notable benefits, Oahu Concrete Professionals are adopting this technology to align with sustainable construction practices in Oahu, Hawaii.

3-Dimensional Printing

3D printing is a widely-spread technology that revolutionizes the construction industry in Oahu, by allowing complex concrete structures to be created with high precision and minimal waste. Oahu Concrete Professionals started to explore the potential of 3d printing for futuristic and intricate customized designs.

Finishing Techniques

The finishing of concrete surfaces has a huge impact on the aesthetic appeal and functionality of the final structure. In achieving the best results, Oahu Concrete Professionals use advanced finishing techniques.

Polished Concrete

This type of finish involves grinding the concrete surface with finer abrasives to have a smooth and glossy result. Applying this method can enhance the durability and curb appeal of your surface while making it easier to maintain.

Stamped Concrete

It is a method of adding pattern and texture to freshly poured concrete to imitate the appearance of bricks, stones, or wood. Stamped concrete is very popular for outdoor spaces like patios and walkways because it offers a durable and stunning surface.

Epoxy Application

Epoxy coatings are applied to concrete surfaces to give a high gloss, protective layer to prevent the buildup of stains, chemicals, and abrasion. This technique is very common in commercial and industrial settings to enhance the durability and aesthetics of concrete floors.

There are a lot of innovative materials and cutting-edge techniques and solutions out there that you can utilize to achieve superior construction work. By adopting these advanced practices, you can ensure that your structures are not just durable and functional but also future-proof to battle the competitive competition in the concrete industry in Oahu. Don't forget to always innovate because change is inevitable.

Contact us today to know more!